Digitalisation & Innovation, Snowmaking & Slope Maintenance

35% fewer machine hours

Piste vehicle manufacturer PRINOTH is both the first choice worldwide as official partner for winter sports events and equally a popular supplier for ski resorts. The innovative, digital technologies from the snowcat manufacturer are also crucial to this – in addition to the latest generation of fuel- saving, clean PRINOTH vehicles, which facilitate resource-saving and cost- effective preparation.

World Cups rely on PRINOTH

Since 2014 the company from South Tyrol has been the official service provider to the International Ski Federation, FIS, for the disciplines of freestyle skiing and snowboarding – a partnership that was extended to all FIS disciplines in 2020. Moreover, the company was previously responsible for piste preparation at the Olympic Games in Lillehammer, Nagano, Turin and Sochi – and it also supplied all the piste equipment for this year’s winter games in China.

In general, PRINOTH is a partner to many ski resorts in the hosting of FIS World Cups. As such, for example, the organising committee of the AUDI FIS Ski Cross World Cup 3 Zinnen Dolomites has been relying on the technology of the company from Sterzing for twelve years, when it comes to construction of the race track.

“Efficiency is paramount in preparation for Ski Cross – things often need to happen quickly here, and snow resources must be used optimally. With its machines and digital solutions, PRINOTH offers us the perfect combination,” says Gabriel Fauster, General Secretary of the Ski Cross World Cup OK Team in Innichen.

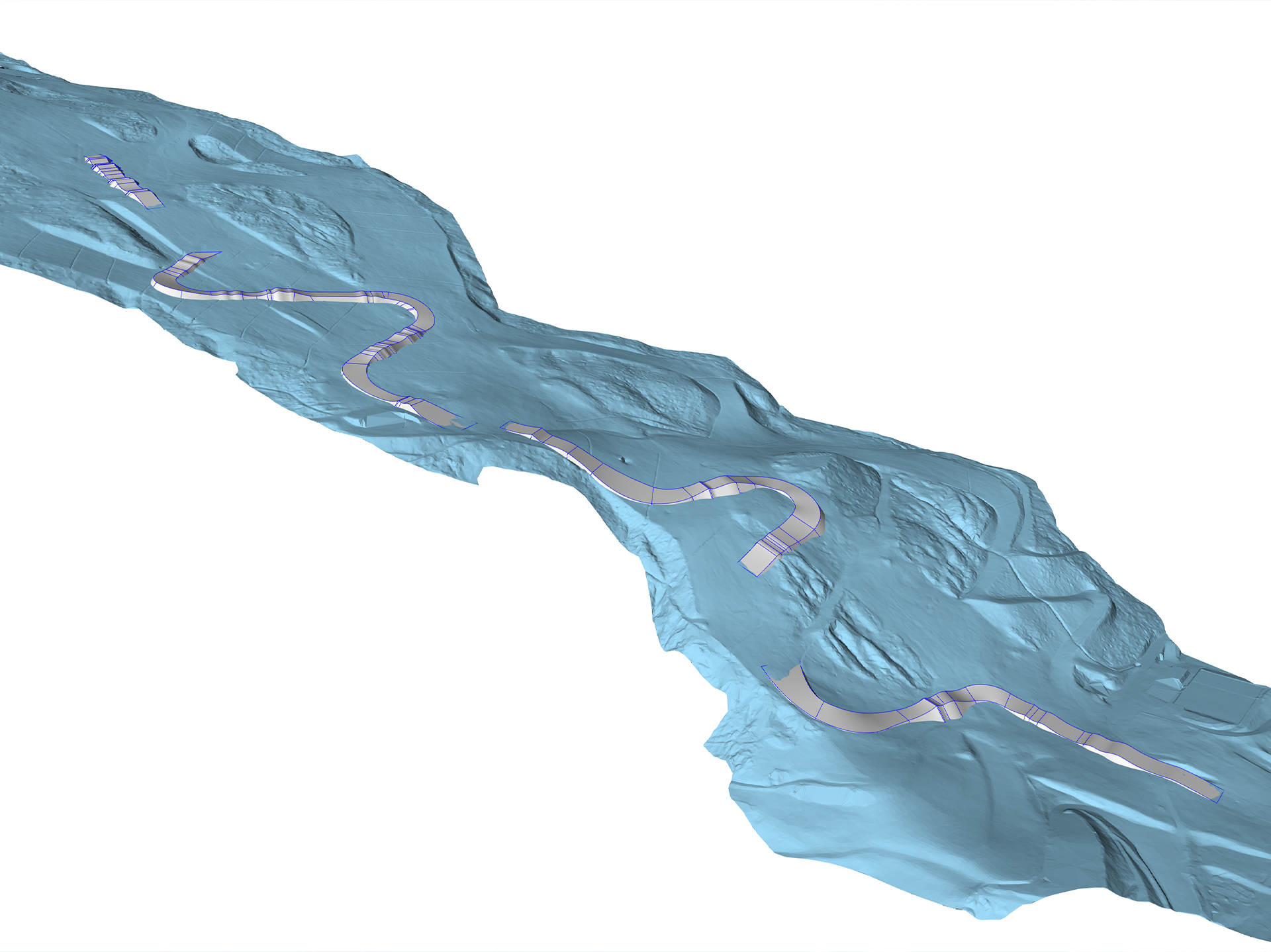

Construction of the course uses not only the PRINOTH X vehicle fleet – designed specifically for shaping and preparing professional parks and race tracks – but also the precise snow measuring software from PRINOTH.

Gabriel Fauster WSV Innichen:

„Unsere 1.100 Meter lange Skicross- Strecke, die zu den längsten im gesamten Weltcupzirkus zählt, wird jedes Jahr leicht abgeändert. Heuer konnten wir an drei Positionen die Stellschrauben drehen. So wurde die Startsequenz anders gestaltet. Im Mittelteil haben wir zwei Mal drei Roller eingebaut – vor zwei Jahren war es ein 5-er Roller. Dadurch werden die Überholmanö- ver in der Folge noch spannender. Und auch der Zielsprung war nicht derselbe, wie bei den letzten Weltcuprennen im Dezember 2019!“

Clever use of data

In 2018, for the first time, the organisers were able to create a digital, 3D model of the race track from previous years – using the history data from the clever PRINOTH snow measuring software. Since then, together with the course designers from F-Tech Snowparks, they have added routinely redesigned elements to the 3D model. During construction, the 3D model was shown on the display in the PRINOTH vehicles and implemented precisely.

However, it is not only the organisers in Innichen who know the advantages of digitalisation when planning and implementing demanding but also safe World Cup tracks; these data are also a top priority for FIS in the construction and competition phase. As such, they are constantly optimising their tracks to make them even safer and more efficient.

Cost-effective and resource-saving construction

Digital snow depth measurement and visualisation from PRINOTH are therefore already an integral part of many FIS World Cups. Using the software solution not only means that tracks can be continuously optimised in terms of safety; it also makes the work deployments of the piste teams significantly faster, more convenient and climate-friendly.

The digital solutions massively simplify the complex Cross track construction, including features in rapid succession, steep turns, waves and jumps. Manual measuring and staking out of the features are therefore no longer necessary. This allows the shapers

Gabriel Fauster WSV Innichen:

“Thanks to the technologies used, we can work many times more efficiently than in previous years. The snow measuring software has enabled us to reduce the machine hours by 35 percent. Even snowmaking can be planned more accurately, and the drivers and shapers can be deployed precisely for their respective area. Overall, everything is much easier to plan and more relaxed; this should be the way forward for the future.” to concentrate entirely on the piste aesthetics. For the organisers in Innichen, that means cost savings of around ten percent in this area.

Perfect solution for everyday work

Nonetheless, using the PRINOTH snow measuring system not only ensures efficiency in the preparation of race pistes and tracks; above all, it has proven itself in everyday ski resort management.

Examples include: optimised ground preparation, targeted adjustments of everyday deployments, prolonging the skiing season. Thanks to the PRINOTH snow measuring system, it is easy to identify potential improvements.

Snowmaking and preparation of the pistes are implemented in a way that is targeted and saves costs. The essential factor here is simple and clear visualisation of the snow depth situation in the ski resort. This forms the basis for all teams – whether on the monitor in the office or in the snowcat.

Gabriel Fauster WSV Innichen:

„Dank der eingesetzten Technologien konnten wir um ein Vielfaches effizienter arbeiten als in den vergangenen Jahren. Dank der Schneemesssoftware konnten wir die Maschinenstunden um 35 Prozent reduzieren. Bereits die Beschneiung konnte präziser geplant werden und die Fahrer sowie Shaper ganz genau für ihren jeweiligen Bereich eingesetzt werden. Insgesamt ist alles viel planbarer und entspannter; dies sollte der Weg für die Zukunft sein.“

For roads and tracks

The applications of the snow measuring systems from PRINOTH are not limited just to snowcats. In use in snow clearing equipment, real-time snow depth visualisation and road layout ensure more targeted distribution of snow masses. This prevents the destruction of track edges and thus saves maintenance costs.

Andreas Muigg, Leiter des Produktmanagements bei PRINOTH:

„Mit unserem System ist der Pistenfahrzeugfahrer in der Lage, in kürzerer Zeit perfekte Kurse zu erstellen. Er sieht die genauen Daten des tatsächlichen Geländes und kann den Kurs nach dem Display in der Kabine aufbauen. Die Softwarelösungen von PRINOTH garantieren Präzision und Effizienz in der Bauphase!“