Cableway & Technology, SI World 2/2024

Becker: best lining for cable cars

Like brake pads in a car – only they also accelerate: The friction pulley linings are one of the most important components of a cable car. It transfers the drive‘s power to the rope through friction, thus setting the system in motion.

Conversely, the lining also ensures the braking of the rope. Accordingly, this safety-critical component is heavily stressed and must therefore be regularly replaced. But now a new manufacturer promises relief in the market: BECKER Treib- und Seilscheiben GmbH from Essen, Germany.

Specialist from the mining industry The company, with roots in the mining industry and almost 125 years of history, can certainly be described as an innovation leader: In 1925, the family business developed a significant product from leather industry waste: the friction pulley lining made of leather.

In the early 1960s, the company delved deeper into conveyor belt service. Rubber and plastic linings gradually replaced the leather linings. To this day, there are no alternatives to these materials – however, there are innovations in materials and processes.

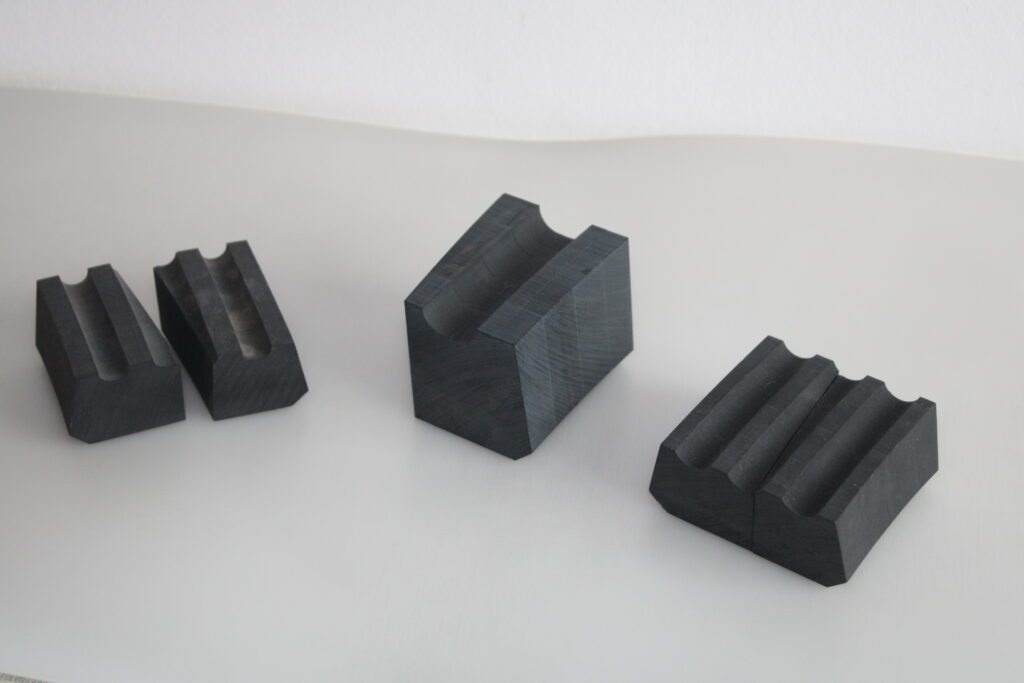

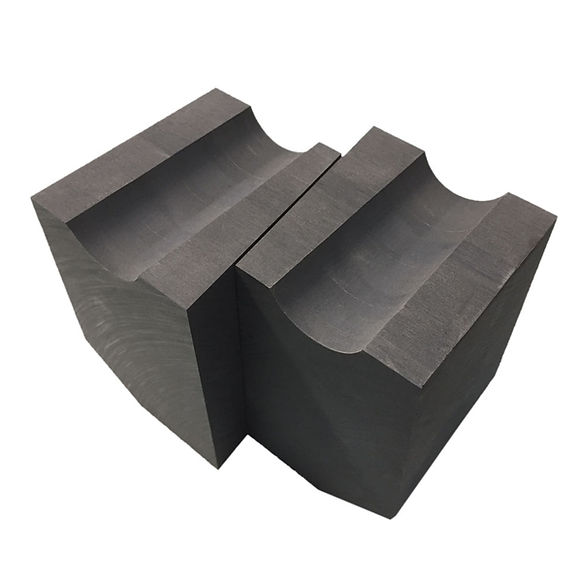

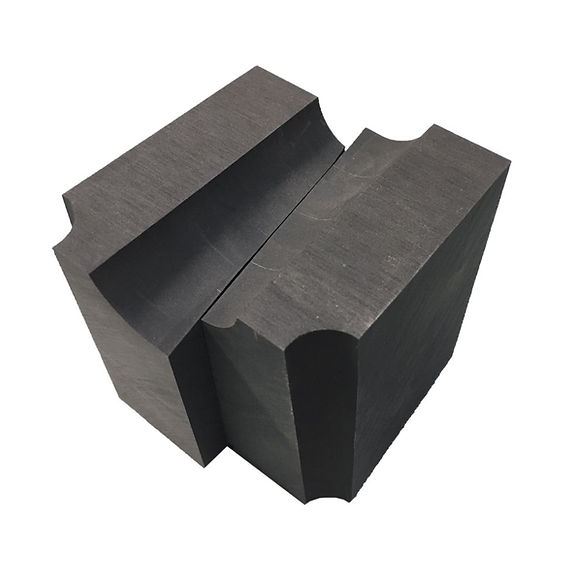

The friction pulley lining

is available in multiple variants and is individually tailored to the cable car.

© Becker Treib- und Seilscheibenfutter GmbH.

In 2022, the company finally entered the cable car industry, reports Sales Manager Michael Lemke:

“A major cable car manufacturer approached us because they were not satisfied with the existing linings. And we immediately set out to design a product that precisely meets the needs of the cable car industry.”

Layering plates

instead of casting blocks The process used, and still used, is one that only BECKER applies worldwide: for the lining, thin plates (22 millimeters) of plastic are bonded, instead of the usual practice of casting entire blocks of plastic.

“Cast blocks often cannot guarantee the homogeneity of material property distribution. Our layered linings, on the other hand, have material properties distributed homogeneously, which greatly increases lifespan,” emphasizes Lemke.

Friction pulley lining, with cuneiform division, triple

Friction pulley lining, with cuneiform division, divided

Friction pulley lining, divided

High coefficient of friction – low wear

The result is TEC-BE-PLAST 913, a friction pulley lining with a high coefficient of friction, very low wear, and a weatherindependent, consistent rope run.

“It is the optimal lining for cable cars – tested by the universities of Aachen and Dresden and certified by the Austrian TÜV,” emphasizes Lemke. A special feature of the material is a high coefficient of friction, which remains above μ = 0.3 even on lubricated ropes.

This is a good value that can withstand comparison. Test results also show very good wear behavior and excellent durability. Additionally, the high weather resistance: “Our linings are in use without problems in Northern Siberia at -40 degrees Celsius as well as in Australia at +40 degrees,” says Lemke.

Michael Becker

Sales Manager at BECKER and Co-author of technical books

Fast and individual manufacturing

The base material for the drive sheave lining is made from high-quality materials. The final production of the lining blocks is precisely tailored to the customer‘s specified data on modern machines.

This is the basis for durability, optimal running properties, and the affordable price, according to Lemke: “Many cable cars and their drive sheaves are unique. Therefore, we manufacture custom linings based on customer drawings, which are ready for use within four to six weeks.”

Installation

The installation is carried out by the operators themselves or by the maintenance service provider. “In the German-speaking region, we can also handle the installation ourselves if needed,” Lemke adds. The sales territory currently covers Europe, Korea, China, Russia, America, and Australia – other countries and regions can also be supplied.

Technical data:

Friction pulley lining TEC-BE-PLAST 91

| Material identifier | black |

| Dynamic coefficient of friction, dry | 0,56 μ |

| Nyrosten N 113 | 0,49 |

| Elasskon II Star | 0,51 |

| Tensile strength | 15,7 MPa |

| Elongration at break | 156 % |

| Surface resistance | 0,5 MΩ |

| Hardness | 45 ShD |

| Density | 1,43 g/cm³ |

| Surface pressure | 200 N/cm² |

| Test speed | 7 mm/sec |