Cableway & Technology, SI World 2/2020

Inauen-Schätti: Renovation for the future

Technical problems, expensive maintenance and heavy rust – the Schindellegi inclined elevator was causing difficulties after just five years in operation. The system connects five Swiss luxury apartments to the building’s own underground car park – or at least it should. However, the inclined elevator was constructed cheaply and poorly, and the manufacturer is moreover no longer operating in the market.

Nonetheless, good advice is not expensive – if you hire INAUEN-SCHÄTTI. “In 2018, the owners commissioned us to perform a status analysis,” Thomas Müller, Head of the Inclined Elevators division at INAUENSCHÄTTI, reports.

The main problem was quickly identified: the electrical installation of the inclined elevator, which runs in the open air in some places, was not compliant with the standard for external installations. “Severe corrosion was causing frequent malfunctions, especially with the automatic doors,” Müller says.

The fact that the devil is often in the detail was also demonstrated by numerous defects on other components of the inclined elevator, such as the drive, transmission and track rails.

Thomas Müller: Head of the Inclined Elevators division INAUEN-SCHÄTTI

“The example of the Schindellegi inclined elevator shows how important quality, reliability and know-how are for smooth operation of ascent aids. As the manufacturer and maintenance specialist of many inclined elevators worldwide, we are the right partner to turn problematic existing systems into means of transport fit for the future.

Indeed, any inclined elevator should actually serve reliably, with little maintenance and virtually faultfree for around twenty years. The system in Schindellegi is guaranteed to do so!”

Technical specification: Schindellegi inclined elevator

- Load capacity 8 p/600 kg

- Travel speed 1.0 m/s

- Altitude difference 13.3 m

- Horizontal track length 25.8 m

- Travel distance 29.0 m

- Gradient 27.4°

- Line width 1.75 m

- Number of stops 5

Control system, doors, motor – all new

It is therefore no wonder that the customers agreed to the extensive renovation plans from INAUEN-SCHÄTTI. As a result, for one thing, a completely

new control system was installed, which can be monitored via remote maintenance. The existing operating panel was also replaced with a new one. In addition, the doors of the five stations had to be replaced.

“The automatic door electronics had inadequate protection, some were even corroded already, and they were responsible for many malfunctions. We therefore replaced the old doors with manual, non-rusting swing doors made of chrome steel,” Müller says. The drive unit (a 2-cable winch) was another problem.

The service brake was defective and the motor manufacturer is moreover no longer operating in the market. INAUEN-SCHÄTTI therefore installed a new 2-cable winch drive with frequency converter and protective cover. “The space in the machine room was very confined and posed a challenge.

With a new opening for the cable, however, we were able to place the drive in the existing machine room,” Müller explains. Nonetheless, building work was required here. The traction and limiter cables as well as a deflecting pulley were likewise reinstalled.

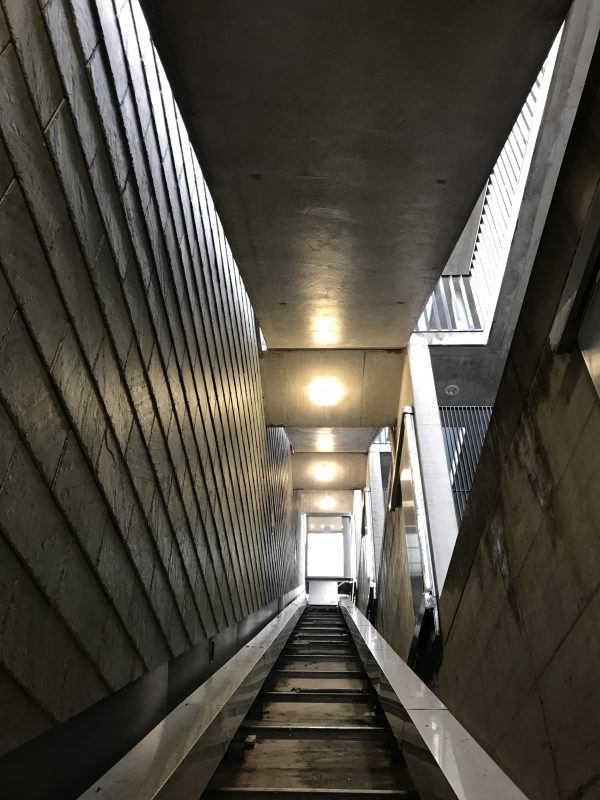

Rust was just one of the problems

revealed by the status report.

Refurbished line, running gear & cabin

The other components of the inclined elevator were not replaced but they were fundamentally refurbished. As such, INAUEN-SCHÄTTI treated the rusty rails

with surface protector (primer + paint) and reinstalled the trackside cables.

The running gear was brought up to date with new switches, cables, control cabinet, speed limiter and overhauled safety brake. The cabin will also continue to be used. However, LED spotlights with an emergency lighting function, a control panel with alarm function and an emergency door now make the journey considerably safer.

The old motor was replaced with a new 2-cable winch drive.

Challenge: lack of documentation

The renovation took INAUEN-SCHÄTTI only five weeks but the planning beforehand was a real challenge, as Müller reports. “As the manufacturer no longer exists, we were missing many documents and detailed drawings.

We even had to measure the elevator shaft and have a 3D model created.” In addition, the work had to be performed very carefully, in order to preserve valuable building material and fixtures. Nonetheless, this is all no problem for the Swiss inclined elevator experts. ts