Maintenance & Service, SI-Alpin, SI-Urban

Rope Maintenance: new developments and tips

Completely it can not be avoided: Ropes fatigue as a result of bending over sheaves, but the process can be delayed by taking care of the rope. On this aspect, the OITAF (International Organization for the Ropeway Industry) presented its empirical values for extending the service life of ropes at Interalpin 2023.

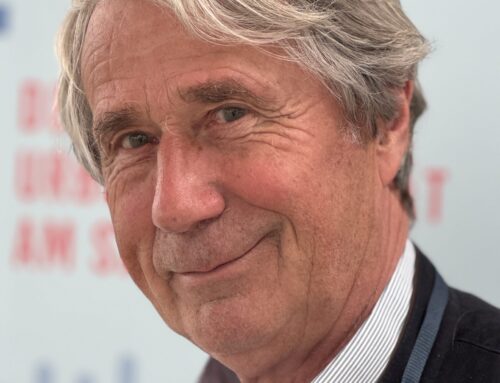

SI spoke to rope expert Konstantin Kühner, rope expert at Jakob Rope Systems about how to properly care for ropeway ropes and what new technological developments there are in this area.

Keeping ropes supple

Another important aspect that helps extend the life of the rope is lubrication. “For the rope to ride well, it should be lubricated regularly with a little oil. After all, too much oil is not optimal either. The lubricant should, of course, match the components. There are also already great developments, such as automatic rope lubricators that dispense oil drop by drop or automatic lubricators that help find the right amount of lubrication,” says Kühner.

“First of all, I have to say, of course you can’t lump all rope functions and ropeway types together, but basically the following applies: Through more than ten thousand bending cycles, the rope gets tired. The easiest way to slow down this process is to run less (by running every half hour and transporting guests in groups) or to run slower, but you have to look at whether this can be implemented from an economic point of view. For example, in bad weather,” says Konstantin Kühner.

Maintain splice on orbits

According to Kühner, the splice is the first thing to fail during operation if the rope is not properly maintained. “It’s important to keep an eye on the splice and shorten the rope in time. The key here is to plan ahead so that I have enough leeway,” Kühner explains.

Predictive maintenance is generally an important keyword in rope maintenance. Many damages could be detected in time during the inspection before they become a problem. “I can detect minor damage such as scratches or grooves with a trained eye during visual inspection and sand them down myself with emery paper. This helps me as an operator to avoid wire breaks occurring quickly and it extends the service life of the rope,” says Kühner.

In general, he says, it’s important to keep an eye on contact points such as groove radii, track and clamps, as well as weather conditions (possible lightning strikes, for example) and travel times.

“In the summer, for example, I often drive continuously, so if I then schedule my inspections or maintenance according to time, it may be that developments have already occurred on the rope by then that would otherwise take longer.

Konstantin Kühner, Rope Expert

“And what can also be very helpful sometimes is to ask questions – for example, to ask employees of other ropeways if you know the error there and have fixed it. That often saves money, too: Because exchanging experiences is usually free of charge,” adds Kühner.

New developments in rope maintenance

AI is also a topic in the ropeway industry. For example, in the search for damage and its localization on the rope. “A French software specialist is researching the use of artificial intelligence in rope inspection. With magnetic inductive testing, I can detect the damage for sure, but I still need visual inspection to assess specific damage. The AI can convert the signal and indicate where the problem is,” Kühner describes.

One bureaucratic innovation is customized operating equipment, even for smaller plants. “This is important because an adapted maintenance plan can be ensured as soon as the plant is commissioned. In the past, that wasn’t followed through quite as consistently.”

In addition, there are now also some software tools that can assist with maintenance planning. “More and more often, a quick check is also carried out with a drone. This increases employee safety,” concludes Kühner.

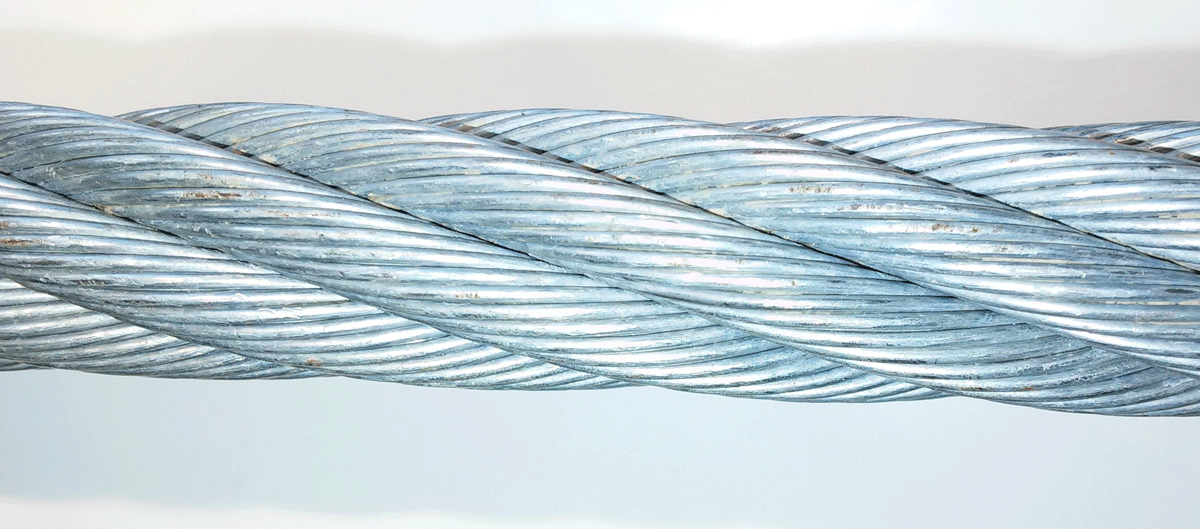

Rope before grinding.

The same rope after grinding. Photos: Konstantin Kühner