Cableway & Technology, Maintenance & Service, SI World 1/2025

100 years of Kissling AG: Revolution with gears

Developing gears further, but also completely rethinking them – this is the claim that KISSLING AG has been articulating for years in its slogan “Revolution with gears”. This year, the Swiss company is celebrating its 100th anniversary.

Headquartered in Bachenbülach near Zürich, the company can look back on an eventful history. Values such as precision, quality, innovation, and customer focus helped it navigate crises and reach new heights. An overview.

1925–1934: The beginnings in Seebach

In 1925, everything began with the company “A. Glutz & Co.”, which manufactured gears and resistance welding machines. In the 1930s – during the Great Depression – the company shrank significantly, but Glutz persevered.

Leander Kissling, then head of the Regensdorf division of Robert Aebi AG, recognized the potential of industrial gears, especially step-shift gears. When the economic situation at Aebi worsened, Kissling joined A. Glutz & Co. as a partner in 1934.

Martin Kissling

CEO and owner KISSLING AG

“The history of KISSLING AG shows how innovation, adaptability, and the determination to overcome difficult times can shape a company. From humble beginnings to becoming an internationally recognized name in gear technology – KISSLING AG is a prime example of Swiss engineerring excellence and entrepreneurial spirit.“

1934–1943: “Glutz Gears” as an innovative brand

Kissling brought fresh energy into the company. Within four months, he developed series of gears for planetary gears and spur gears as well as step-shift gears. These were particularly successful during the crisis period, as many workshops converted their belt drives to single drives.

From 1938 onward, the company introduced standardized gear ratios, which improved both prices and delivery times. These innovations made “Glutz Gears” well known throughout Switzerland.

1943–1980: KISSLING AG as a player in the ropeway industry

In 1943, Leander Kissling took over the company and renamed it “L. Kissling & Co.”. Under his leadership, new technologies such as case-hardened and flank-ground gears were introduced. KISSLING became one of the first companies in Europe to produce such gears on a series basis.

The 1950s and 1960s brought rapid growth. New types of gears and custom designs were developed, including gears for ski lifts and ropeways. Success in this area led to strong demand, making ropeway gears an important revenue driver. In 1980, the company was converted into a corporation and the share capital was distributed within the family.

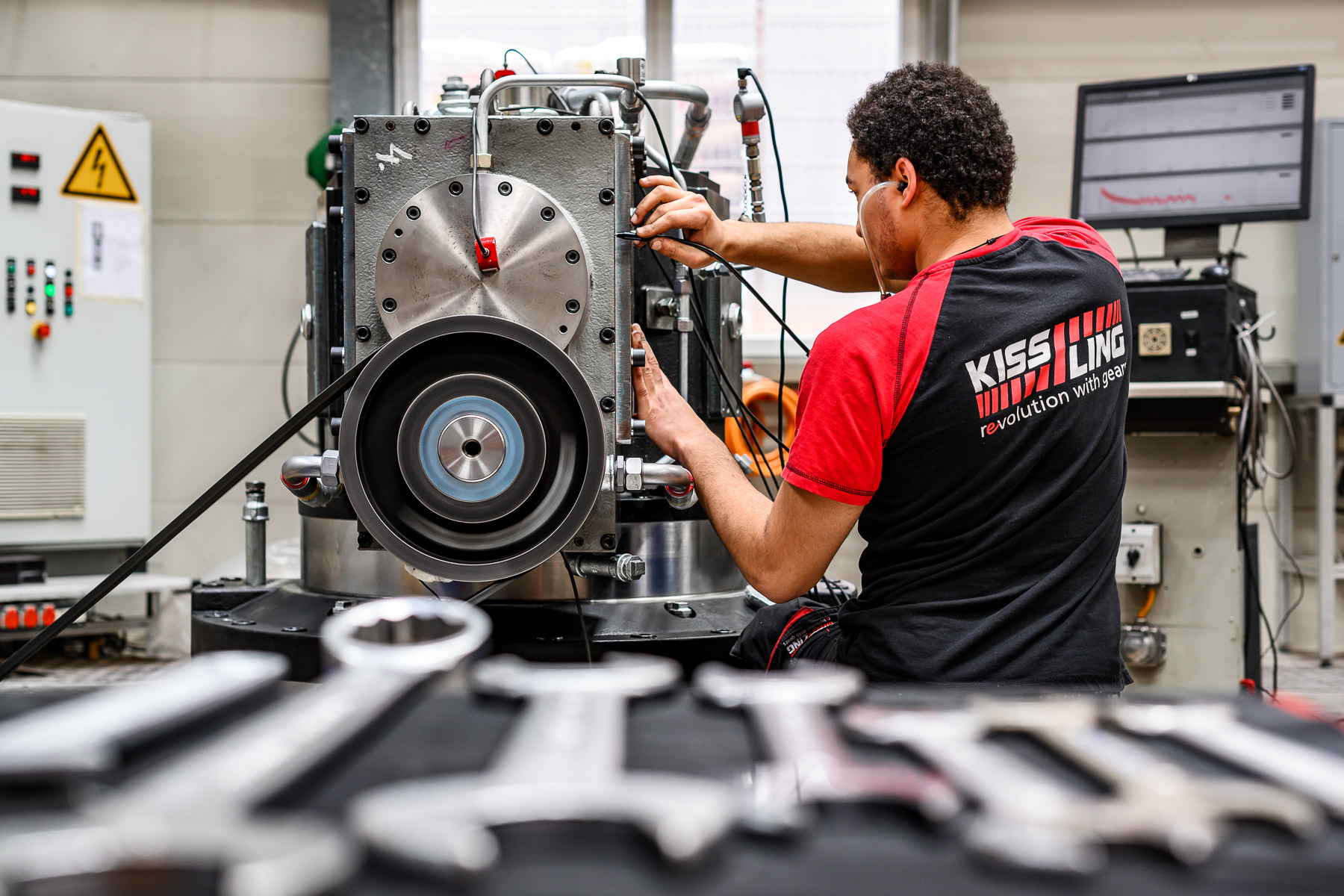

Much in stock:

The well-equipped warehouse in Bachenbülach near Zurich ensures that gearbox overhauls can be carried out quickly at KISSLING.

1981–1999: POMA supplier, software lab – and the crisis

The 1980s and 1990s were marked by both growth and challenges. KISSLING became the exclusive supplier for POMA, a leading ropeway manufacturer, and introduced innovative software solutions such as KISSsoft, which was later spun off as an independent company. A prolonged recession put KISSLING AG in a challenging economic position.

It was only toward the end of the 1990s that the company managed to get back on track through a successful turnaround. During this time, the Kissling family made a groundbreaking decision: the production of gears and shafts was outsourced to selected third-party manufacturers who met the high quality standards of KISSLING AG.

This strategic realignment proved to be one of the best ideas in a long time, laying the foundation for sustainable recovery and future growth.

In the heart of Switzerland

KISSLING has been based in Bachenbülach near Zurich since 2009.

2000s: Amusement parks, the US market, and ASTRO

After successful restructurings, the company recovered and got back on a growth path. Yet, new economic challenges continually demanded flexibility and courage to maintain its market position. The quality and reliability of KISSLING gears found new applications.

Renowned amusement parks worldwide chose KISSLING products to offer their guests safe and smooth experiences. Expansion into North America was driven by a collaboration with ARTEC. With a strong partner by its side, KISSLING established itself in this market and reached new customer segments.

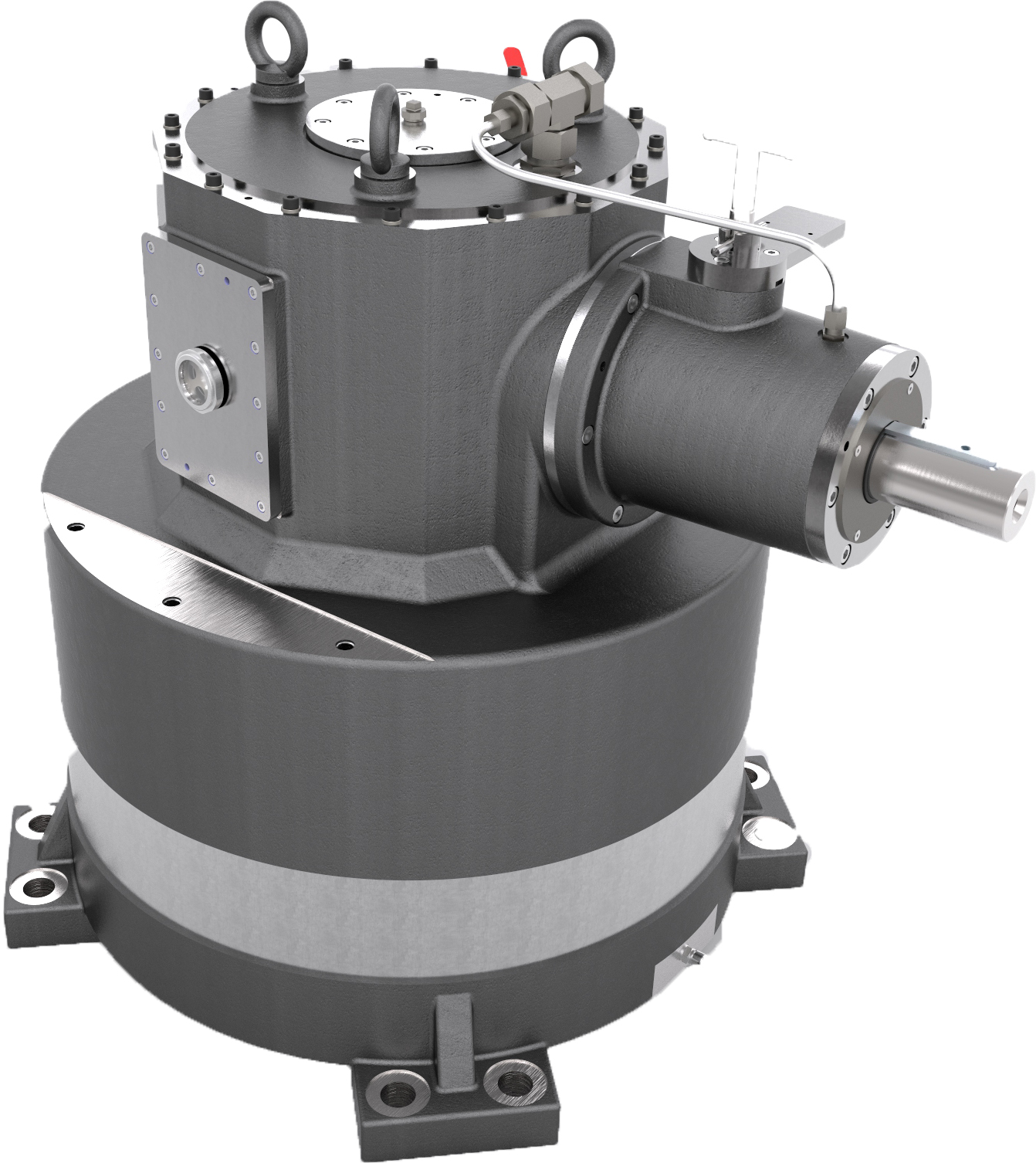

In 2006, KISSLING introduced the ASTRO gears – a groundbreaking development specifically designed for high precision and load-bearing capacity, further strengthening the company’s technological edge.

In 2009, the next important step was taken with the move to Bachenbülach. At the new location, the foundation for further growth was laid, featuring modern infrastructure and expanded production capacities.

Roman Siegfried

Head of Sales & Marketing KISSLING AG

“Since 2012, Martin Kissling has been the sole owner of KISSLING AG. With his visionary approach, he brought fresh momentum to our company and initiated

a comprehensive restructuring that continues to play a key role in its success today. With foresight and a strong focus on growth and quality, he continues to set new impulses that shape and strengthen the company sustainably.“

2012–2015: New structure, new gears

Since 2012, Martin Kissling has been the sole owner of KISSLING AG. Under his leadership, strategic decisions were made to modernize the company’s structure and increase process efficiency. The development of new products, such as the successful Sirius series, and the opening of additional markets were central to his strategy.

Martin Kissling placed particular emphasis on enhancing customer focus and the company’s innovative capabilities. His approach enabled KISSLING AG to position itself as a reliable and forward-looking partner in a highly competitive market.

An example is the Wega490, launched in 2013. With this product, KISSLING brought a double-conical planetary gear to the market that is distinguished by its high rotational speed of 10,000 rpm and is used in various high-tech applications.

In 2014, the Sirius-CS 125 followed immediately. The star planetary gear set new standards in gear technology with 400 kW at 20,000 rpm and once again demonstrated the strength of KISSLING in demanding applications.

Shaping values

Values such as precision, quality, innovation and customer orientation helped KISSLING through crises and led it to new heights.

2015–2021: New certifications, new products, …

In 2016, KISSLING received the environmental certification ISO 14001 and the occupational safety certification OHSAS 18001. These awards underscored the company’s commitment to sustainability and safe working conditions.

In 2017, a significant year for the ropeway industry, KISSLING developed the new, compact, and small SKP ropeway gears, opening up new possibilities in ropeway technology and impressing mountain lift operators with innovative solutions.

In other sectors too, much was happening: in 2018, KISSLING presented a new concept for turbo gears, specifically development for test benches, achieving an impressive 65,000 rpm.

…and new partners

Finally, in 2019, KISSLING secured a significant partner in the USA with LONE WOLF. This step marked another milestone in the company’s internationalization and significantly strengthened KISSLING’s presence in the North American market.

In 2020, the SKP ropeway gears were successfully introduced in China, resulting in sales of over one million Swiss francs and underpinning KISSLING’s international success. Collaboration with CRYOSTAR marked another major success in 2021, with KISSLING being recognized as a key supplier and further

strengthening its position in strategic partnerships.

Customer in focus

In the years 2022 to 2024, KISSLING implemented a new strategy aimed at being even closer to the market and the needs of customers.

2022–Today: Closer to the market, end customer in focus

From 2022 to 2024, KISSLING implemented a new strategy aimed at being even closer to the market and the needs of its customers. The focus was on increased direct cooperation with end customers in order to better understand specific requirements and develop tailor-made solutions.

Many more onsite customer meetings were held to nurture personal relationships and respond more quickly to individual wishes. This strategy not only enhanced customer satisfaction but also increased market share in various sectors.

With the development of the Sirius CS-175, KISSLING once again set technological benchmarks. This gear achieves an impressive output of 1.4 MW and demonstrates the company’s innovative strength.

During the years 2022 to 2024, the Sirius series was further developed to establish a strong second pillar for the company. Building on the success of the Sirius CS-175 with its 1.4 MW output, KISSLING invested in new technologies and improved production processes to make the Sirius series even more versatile and powerful.

In keeping with the motto: develop gears further, but also completely rethink them. Or as KISSLING puts it: “Revolution with gears!”