Cities, SI World 2/2019

UP bus: Sometimes it drives, sometimes it hovers

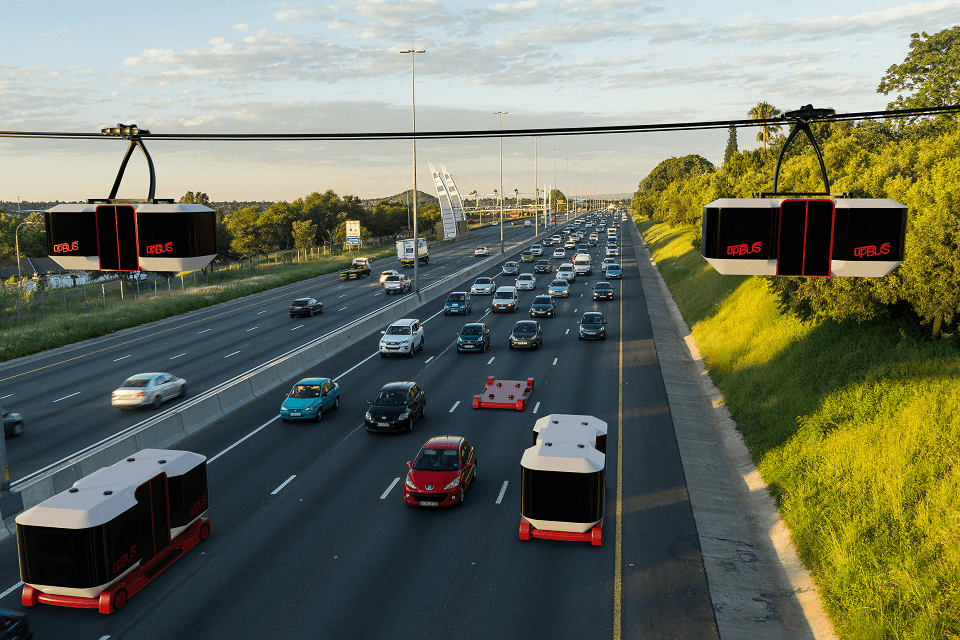

The scenario: On the station forecourt, commuters switch from the train to autonomously driven electric minibuses waiting in the taxi stands. After a few hundred metres, the vehicles gradually enter a cable car station. There, the buses engage on the cable. The chassis including motor and battery block is left behind and the battery is recharged.

From now on, the journey is over the rooftops to one of the next cable car stations. There, the buses gain a new chassis, are released from the cable and roll the last few metres across the road to their destination. This is how local transport could look in cities in the future, Professor Kai-Uwe Schröder and his research associate Tobias Meinert from the Institute of structural mechanics and lightweight construction at Aachen technical university believe.

Together with the department of maximum-frequency electronics, the two are researching a system called upBUS. In this hybrid mobility concept, the vehicle switches between aerial cable car and autonomous bus mode.

Unlike a conventional connection between a cable car system and ground-based systems such as buses, for which passengers have to alight, the passengers of the hybrid vehicle can remain in the gondola. This allows continuous mobility of the hybrid vehicle on two levels.

A wooden model of upBUS will be presented at trade fairs from autumn 2019. Photos: TU Aachen

Kai-Uwe Schröder, head of the institute of structural mechanics

and lightweight construction at Aachen technical university

“Many cities and metropolitan regions around the world are on the verge of transport and environmental collapse as a result of the use of cars. To relieve the strain on the generally already overcrowded streets, the air space above street level represents an appropriate option. upBUS offers the solution to this, by combining the

development of two different transport systems – urban cable cars and autonomously driven electric buses.”

The system in detail

Following the example of the German city of Aachen, researchers have developed an initial upBUS mobility concept. The upBUS gondolas should

each be able to carry 35 passengers, operate on a 30-second cycle and transport up to 6,000 passengers per direction and hour. Three components are especially important here:

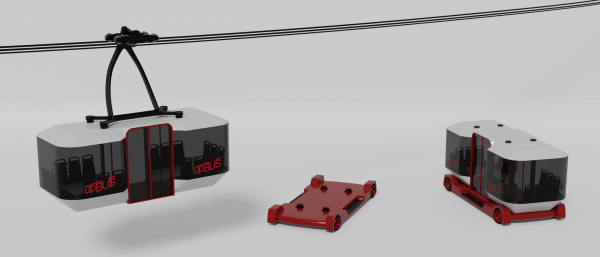

Bus

The driving module of the first prototype needs neither to travel faster than walking speed nor to have a large electric range. Expensive developments such as axle layouts aretherefore omitted.

Inside the driving module are the batteries and electric motors, with all the components required to power the vehicle in road vehicle mode. More elements will be fitted in the later series module.

Gondolas

The passenger compartment consists of a primary and a secondary structure. The primary structure comprises a roof and a base frame as well as four inclined supports, which connect the roof frame to the base frame. Through the inclined position of the supports, the flow of forces in cable car mode is transmitted from the hanger to the load-bearing structure in a way that is as advantageous as possible.

All the elements of the primary and secondary structure are made of profiles in a light metal alloy, which are welded together. The secondary structure serves to attach cladding elements of the passenger compartment, including the glazing.

Four profile bars arranged vertically also connect the roof frame to the base frame and serve to attach the doors on one side and seating on the

other.

Interfaces

Most transmodular mobility concepts nowadays are still impeded by lack of a highly autonomous and redundant interface. The iBOSS space interface precisely fulfils the required conditions. It is designed with redundancy, can operate highly autonomously and has all the necessary transmission mechanisms.

The iBOSS interface is designed as a “4-in-1 system”. “4-in-1” refers to the ability to transmit loads, electrical energy, data and heat by means of a single interface. This combination is unique worldwide.

Research status and outlook

The scientists around Kai-Uwe Schröder have already produced a scaled-down wooden model of the bus, which will be presented at mobility trade fairs from autumn 2019. The bus prototype has been in development since June 2019 and will be tested on a DOPPELMAYR cable car test stand in November 2020.

To reduce costs, anything unnecessary will initially be omitted, such as speed, range, comfort etc. The later series module will naturally be equipped appropriately. By contrast, the entire iBOSS system (and therefore also the interface) has been in development since 2010.

Experts from all over Germany have designed, developed and produced this space satellite system in a joint project, with funding of ten million euros. “We thought about how the coupling could be used on Earth and that is how we came up with upBUS,”Meinert concludes.

The first test route on which upBUS will run – and actually transport passengers – will be constructed in 2023. ts